Overview of the Yamanashi Factory

The Yamanashi Factory of Oshino Electric was established in 2012.

Currently, the facility operates 18 molding machines and specializes in the production of transparent resin components.

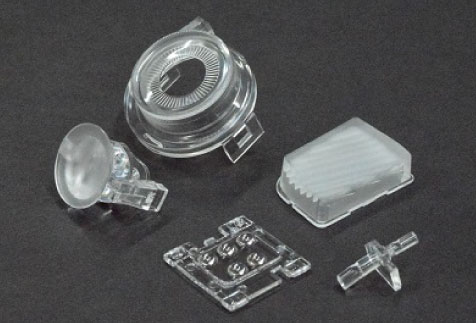

Specialization in Transparent Resin Products

We specialize in molding transparent resins such as PMMA and PC, which are known for their strict manufacturing requirements.

Our factory is capable of producing complex and high-precision shapes, even with challenging product geometries.

By focusing exclusively on optical components made from transparent resin—such as light guides and lenses—we continuously accumulate know-how and expertise in advanced manufacturing.

Main Products:

- Automotive optical components (light guides, lenses, diffusers, LED light sources)

- Optical components for general industrial applications

Cleanroom Environment

Unlike most molding facilities, all molding machines are installed inside a cleanroom, ensuring a highly controlled and hygienic production environment.

We maintain a Class 8-equivalent cleanroom, minimizing contamination and significantly reducing the risk of defects caused by foreign particles.

High Quality

Under the "OL : Oshino Lamps" brand, we have delivered a wide range of products—mainly for aerospace and automotive applications—to customers both in Japan and overseas for many years.

Our strengths lie in our uncompromising commitment to quality, our ability to meet demanding customer requirements, and our advanced facilities and technical capabilities.

Transparent resin products PC

Transparent resin products PC

Transparent resin products PMMA

Transparent resin products PMMA

Production Process of Optical Components

1. Drying

Transparent resin pellets, which serve as raw material, are placed into a dryer to remove moisture.

2. Molding

The dried resin is fed into a molding machine and heated to approximately 230°C to 300°C.

Once melted into a liquid state, the resin is injected into a mold and allowed to cool and solidify over a set period.

3. Inspection

Finished products are placed onto trays and inspected by quality control personnel.

During this step, the products are carefully checked for scratches, contamination, or other defects.

4. Packaging and Shipping

After passing inspection, the products are packed into shipping cartons.

Items made from resins that require temperature control are stored in climate-controlled warehouses until shipment.

Design and tooling

Fully Integrated Production at Our Domestic Factory

Oshino has in-house departments dedicated to the design and development of optical components, including light guides and light conductors, as well as its own mold-making facility.

We utilize advanced CAE-based optical analysis and have extensive expertise specifically in optical component design and manufacturing.

With our design team, tooling workshop, molding facility, and assembly plant all operating in close coordination, Oshino provides rapid product launches and strong support for your new product development.

Technical Overview of Light Guides

Overview of Equipment at Yamanashi Factory

- Injection Molding Machines

- 18 units ranging from 30 to 350 tons

- Machining Centers

- 4 units, including 1 ultra-precision machining center: UVM-700C(H)

- Dimensional Measurement Equipment

- KEYENCE VK-X3000 – Laser Microscope

KEYENCE XM-T2200 – Contact-Type High-Precision 3D Measurement System

KEYENCE VL-500 – Non-Contact High-Precision 3D Measurement System

KEYENCE VR-5200 – 3D Surface Profiler

KEYENCE IM-6120 – Image Dimension Measurement System

- Optical Measurement Equipment

-

KONICA MINOLTA T-10MA – Illuminance Meter

TOPCON SR-UL1R – Spectroradiometer

Radiant Vision Systems ProMetric I (IC-PMI2) – Imaging Colorimeter and Luminance Meter

(As of September 2022)

Access

601-2 Shirai-cho Koufu City, Yamanashi Pref, 400-1502

TEL : +81(0)55-266-5515 FAX : +81(0)55-266-5516

![株式会社押野電気製作所 [本社] 〒140-0011 東京都品川区東大井 5−12−10 大井朝陽ビル4階TEL:03-3471-8548(代)](/wp-content/themes/oshino/images/common/footer-about-en.svg?20211228)